Third Party Certification – Nationally Recognized Testing Laboratory

Purpose of Third-Party Certification (NRTL)

Manufacturers submit samples of their products to a NRTL such as UL for testing before they are manufactured on a large scale. It is then presumed that the manufacturer will maintain the same quality in the future production of the same item. Such testing facilities also perform on-site inspections to ensure that the manufacturer continues to manufacture the product by their standards.

For example, if the product passes the exhaustive tests of UL in accordance with established standards, it is added to the official UL published list and the product is then known as “Listed by Underwriters Laboratories, Inc.”

Such UL items usually have a UL label attached directly to the product. In some cases, this UL “label” is molded or stamped into the merchandise.

Note: This same procedure is used by other NRTL that are approved by OSHA.

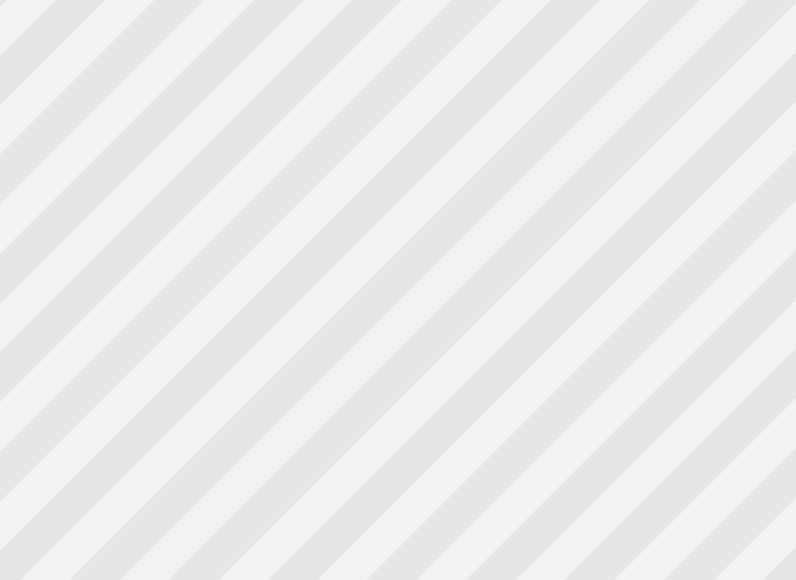

An item approved by NRTL, however, is not necessarily approved for all uses. Rather, a testing label means that the item or device, as labeled, is safe only for the purpose for which it was intended. (See Illustration 1 below)

Illustration 1

Design Tip: Once equipment has been approved, it is not to be modified in any way, but must be used as instructed by the manufacturer.

For example, the wiring or any of the other elements are not to be changed out or rearranged in a manner that does not comply with the listing and labeling of the nameplate on the equipment or accompanying literature.

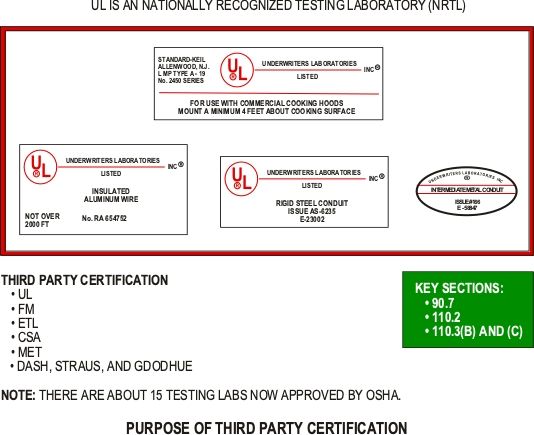

UL White Book (NRTL)

The UL White Book, known in the electrical industry as the “General Information Electrical Construction, Hazardous Locations, and Electrical Heating and Air Conditioning Equipment Directory,” provides a service for the classification of products that have been determined to meet the appropriate requirements of the applicable international publication(s). For those products that comply with the requirements of an international publication(s), the Classification Marking may appear in various forms as authorized by UL.

For example, a form may include and illustrate the word “Classified” with a control number assigned by UL. The product name as indicated in this Directory under each of the product categories is generally included as part of the Classification Marking text but may be omitted when, in UL’s opinion, the use of the name is superfluous and the Classification Marking is directly and permanently applied to the product by stamping, molding, ink stamping, silk screening, or similar processes.

Separable Classification Markings (not part of a nameplate and in the form of decals, stickers, or labels) will always include four elements: UL’s name and/or symbol, the word Classified, the product category name, and a control number.

The complete Classification Marking will appear on the smallest unit container in which the product is packaged when the product is of such a size that the complete Classification Marking cannot be applied to the product or when the product size, shape, material, or surface texture makes it impossible to apply any legible marking to the product. When the complete Classification Marking cannot be applied to the product, no reference to UL on the product is permitted. (See Illustration 2 below)

Illustration 2

Design Tip: Designers, installers, and inspectors use the UL White Book to determine if certain wiring methods and equipment are indeed listed and labeled and are apt for a particular installation according to their condition of use.

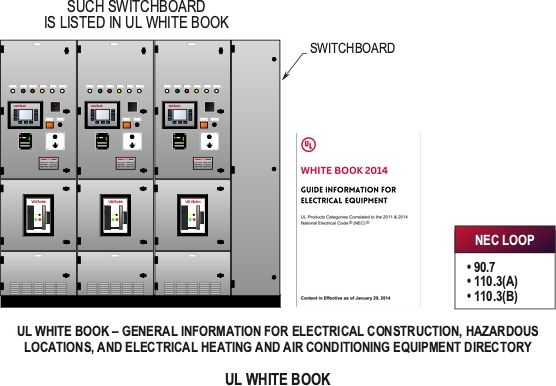

Approval

OSHA requires conductors and equipment to be accepted only when approved. The definition of approved is to be acceptable to the AHJ per Article 100 in the NEC. OSHA 1910.303(a), 1910.399, NEC 110.2 and NEC 500.8(A) now have the same requirements considering the acceptability of components, wiring methods, and equipment. The AHJ will usually require third-party certification of all equipment. For third-party certification, a NRTL performs tests to verify if the equipment will do what it is designed to do and still be safe to the user. The only problem with accepting equipment that is not certified by a third party (NRTL) is that the AHJ takes the sole responsibility that the equipment is safe.

Design Tip: OSHA demands third-party certification by an independent NRTL for any and all electrical equipment designed and installed in industrial locations. Custom-made equipment is acceptable where the equipment needed is not available to be purchased and is not listed and labeled by a Nationally Recognized Testing Laboratory (NRTL). (See Illustration 3 below)

Codes and Standards to Review

(1) NEC 90.7

(2) NEC 110.2 and NEC Article 100

(3) NEC 110.3(B) and (C)

(4) NEC 500.8(A)

(5) OSHA 1910.303(a) and 1910.399

(6) OSHA 1926.403(a)

Illustration 3

Examination, Installation, and Use of Equipment

All electrical equipment and work must be related to the OSHA regulations and comply with the provisions of standards and installation instructions of NRTL that have tested and certified the equipment.

Such Nationally Recognized Testing Laboratories (NRTL) and certifying organizations are:

(1) Underwriters Laboratories (UL)

(2) Factory Mutual Engineering Corp. (FM)

(3) Electrical Testing Laboratories (ETL)

(4) MET Testing Company, Inc.

(5) Dash, Straus, and Goodhue, Inc.

(6) Canadian Standards Association (CSA)

(Limited Certification)

Note: There are others.

Examination

The NEC, OSHA, and NFPA 70E do not include detailed requirements for wiring inside of electrical equipment. Information pertaining to the internal wiring of equipment is usually found in individual standards that contain special requirements for installing the equipment concerned.

It is not the intent of the NEC and OSHA to take away the authority of inspectors to examine and approve equipment. However, the NEC, OSHA, and NFPA 70E indicate that the rules pertaining to the internal construction of equipment are usually investigated and approved by a qualified testing laboratory.

The NEC does not make a flat rule to the effect that all electrical equipment shall have third-party certification of equipment by independent NRTL per 90.7, 110.2, 110.3, and 500.8(A). OSHA, on the other hand, does require electrical equipment to have third-party certification (NRTL) for the safety of personnel using such equipment per Subpart S to 1910.303(a).

In judging and evaluating electrical equipment that is installed in the employee workplace, the following steps shall be followed:

(1) Judge the wiring installation to ensure that it complies with the provisions of NFPA 70E. Evaluate the equipment for suitability for installation and use according to nameplate ratings and instructions. List the appropriate standard for such equipment.

For example, every product listed in the UL Electrical Construction Materials Directory (Green Book) is required to be installed as described in the application data given with the listing in the book. It becomes the responsibility of the AHJ to decide and determine the suitability of electrical equipment that has not been tested and certified by a NRTL or qualified testing laboratory.

(2) Mechanical strength and durability of enclosures, raceways, etc. enclosing electrical parts and wiring shall be adequate to provide proper protection of such elements.

(3) Electrical insulation shall be installed by Table310.4 and loaded according to the ampacities of Table 310.16 for systems rated at 2000 volts or less. Insulation of conductors may be checked with any good insulation resistance tester.

(4) Equipment and insulation shall be sized and selected to operate safely under normal conditions of use and also under abnormal conditions without adverse heating effects. [See 310.14(A)(3)]

(5) Electrical equipment shall be equipped with shields, etc. to deflect the arcing effect and limit the burning effect of the arc. (See 110.18)

(6) Electrical equipment with components shall be classified by its type, size, voltage, current capacity, and specific use.

An evaluation shall be made to verify that the type and size of equipment is being supplied with the proper voltage and is loaded to a value no greater than it is designed to carry. [See 90.7 and 110.3(B) and (C) and OSHA 1910.399.]

Codes and Standards to Review

(1) NEC 110.3(A)

(2) OSHA 1910.399

(3) OSHA 1910.303(b)(1)

(4) OSHA 1926.403(b)(1)

Installation and Use

OSHA’s relationship to electrical equipment is very clear in 1910, Subpart S, Electrical. Electrical equipment shall have third-party certification for the essential safety of the equipment and components used to assemble electrical installations.

For the safety of personnel utilizing such equipment, OSHA requires the following:

Utilization equipment. Equipment that utilizes electric energy for electronic, electromechanical, chemical, heating, lighting, or similar purposes.

Approved. Acceptable to the authority enforcing Subpart S. The authority enforcing Subpart S is the Assistant Secretary of Labor for Occupational Safety and Health. The definition of “acceptable” indicates what is acceptable to the Assistant Secretary of Labor, and therefore approved within the meaning of Subpart S.Acceptable. An installation or equipment is acceptable to the Assistant Secretary of Labor, and approved within the meaning of Subpart S:

(1) If it is accepted or certified, listed or labeled, or otherwise determined to be safe by a nationally recognized testing laboratory, or

(2) With respect to an installation or equipment of a kind that no nationally recognized testing laboratory accepts, certifies, lists, labels, or determines to be safe, if it is inspected or tested by another Federal agency, or by a state, municipal, or other local authority responsible for enforcing the occupational safety provisions of the National Electrical Code (NEC), and found in compliance with the provisions of the NEC as applied in Subpart S, or

(3) With respect to custom-made equipment or related installations that are designed, fabricated for, and intended for use by a particular customer, if it is determined to be safe for its intended use by its manufacturer on the basis of test data, which the employer keeps and makes available for inspection to the Assistant Secretary and his or her authorized representatives.Custom-made equipment should be designed and built according to the provisions listed in UL 508 or one of the C series published by ANSI, based on the type equipment involved.

The customer specifies to the manufacturer the function that its equipment must perform. (See Illustration 4 below)

Labeled. Equipment is “labeled” if there is attached to it a label, symbol, or other identifying mark of a nationally recognized testing laboratory:

(1) That makes periodic inspections of the production of such equipment and

(2) Whose labeling indicates compliance with nationally recognized standards or tests to determine safe use in a specified manner.

Listed. Equipment is “listed” if it is of a kind mentioned in a list that:

(1) Is published by a nationally recognized laboratory that makes periodic inspection of the production of such equipment and

(2) States that such equipment meets the nationally recognized standards or has been tested and found safe for use in the specified manner.

Accepted. An installation is “accepted” if it has been inspected and found by a nationally recognized testing laboratory (NRTL) to conform to specified plans or to procedures of applicable codes.

Certified. Equipment is “certified” if it bears a label, tag, or other record of certification that the equipment:

(1) Has been tested and found by a nationally recognized testing laboratory to meet nationally recognized standards or be safe for use in a specified manner, or

(2) Is of a kind whose production is periodically inspected by a nationally recognized testing laboratory (NRTL) and is accepted by the laboratory as safe for its intended use.

Design Tip: OSHA requires all electrical equipment, where available, to be listed and labeled by a Nationally Recognized Testing Laboratory (NRTL). UL and FM are laboratories without limited certification that are accepted for industrial locations.

However, if such needed electrical equipment is not listed, labeled, and available, then custom-made equipment that complies with the requirements of the Assistant Secretary is acceptable. OSHA recognizes a nationally recognized testing laboratory (NRTL), while the NEC recognizes a qualified testing laboratory (QTL).

There is a conflict in the standards due to the change in the 1981 NEC, which changed the wording from nationally recognized testing laboratory to qualified testing laboratory.

Codes and Standards to Review

(1) NEC 110.3(B) and (C)

(2) OSHA 1910.303(b)(2)

(3) OSHA 1926.403(b)(2)

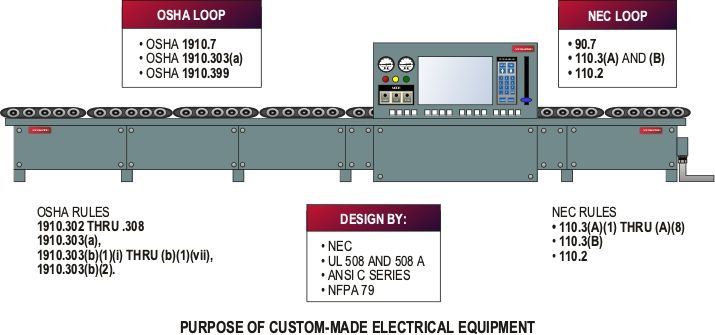

Purpose of Custom-Made Electrical Equipment (NRTL)

OSHA requires all electrical equipment, where available, to be listed and labeled by a nationally recognized testing laboratory (NRTL). However, if such electrical equipment is not listed, labeled, and available, then custom-made equipment that complies with the requirements of the Assistant Secretary of Labor is acceptable. (See OSHA 1910.399)

Custom-made equipment (one of a kind) or related installations is equipment that is designed, fabricated for, and intended for use by a customer, where it is determined to be safe for its intended use by its manufacturer on the basis of test data that the employer keeps and makes available for inspection to the Assistant Secretary and his or her authorized representatives in the field (OSHA inspectors).

Custom-made equipment should be designed and built by the provisions listed in the NEC, UL 508, NFPA 79, or one of the C series published by ANSI, based on the type or equipment involved. The customer specifies to the manufacturer the function that its equipment shall perform. (See Illustration 4 below)

Codes and Standards to Review

(1) NEC 110.3(B) and (C)

(2) OSHA 1910.303(b)(2)

(3) OSHA 1926.403(b)(2)

Illustration 4

OSHA’s Relationship to Electrical Equipment

OSHA 1910.7, 1910.303(a), 1910.399 (ACCEPTABLE), NEC 110.2, 110.3(A), (B), and (C), and Article 100 (Definitions of Approval)

The requirements set forth in OSHA 29 CFR, 1910.302 through 1910.308 pertain to electrical equipment installed before and after certain mandatory dates listed in Subpart S. All electrical utilization systems and pieces of equipment that were designed, installed, and inspected after March 15, 1972 shall comply with all the provisions according to OSHA 1910.302 through 1910.308. All major replacement, modification, repair, or rehabilitation performed after March 15, 1972 on such systems and equipment shall comply with these requirements.

Note: Also review carefully the information in each section outlined in August 13, 2007.

There are certain provisions in OSHA 1910.302 through 1910.308 that are intended to apply only to electrical systems and equipment installed after April 16, 1981, which are not meant to be retroactive. These non-retroactive requirements and the electrical installations and equipment they apply to are listed in OSHA 1910.302(b).

Design Tip: Major replacements, modifications, or rehabilitation (as outlined in OSHA regulations) include work similar to that involved where a new building or facility is built, a new wing is added, or an entire floor is renovated.

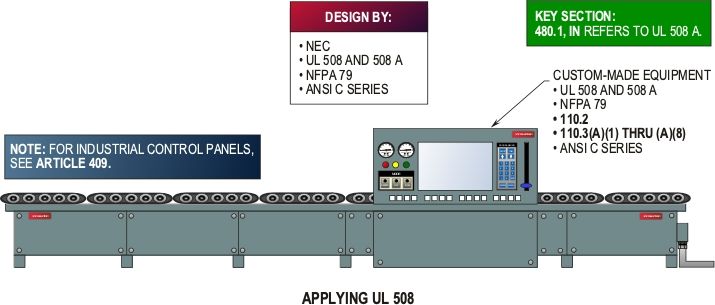

Purpose of UL 508 and 508A (NRTL)

UL 508 and 508A contains basic requirements for products covered by Underwriters Laboratories, Inc. under its Follow-Up Service for this category within the rules and regulations of the Standard. These requirements are based on sound engineering principles, research, records of tests, field experience, and an appreciation of the problems of manufacture, installation, and use derived from consultation with and information obtained from manufacturers, users, inspection authorities, and others having specialized experience. They are subject to revision as further experience and investigation may show is necessary or desirable.

A product that complies with the text of UL 508 and 508A will not necessarily be judged to comply with the Standard if, when examined and tested, it is found to have other features that impair the level of safety contemplated by these requirements.

A product employing materials or having forms of construction differing from those detailed in the requirements of this Standard may be examined and tested according to the intent of the requirements and, if found to be substantially equivalent, may be judged to comply with the Standard.

Applying UL 508

The requirements of UL 508(A) cover industrial control devices, and device accessories thereto, for starting, stopping, regulating, controlling, or protecting electric motors. Such requirements also cover industrial control devices or systems that store or process information and are provided with an output motor control function(s). This equipment is for use in ordinary locations in accordance with the NEC.

Requirements also cover industrial control panels that are assemblies of industrial control devices and other devices associated with the control of motor-operated and related industrial equipment. Examples of devices in an industrial control panel are disconnecting means, motor branch-circuit protective devices, temperature control devices, electrical instruments, etc. (See Illustration 5 below)

Illustration 5

For example, an industrial control panel for the control of metal-working machine tools or plastics machinery is judged on the basis of compliance with the applicable requirements of this Standard as well as the requirements in the Standard for Industrial Machinery, NFPA 79.

Design Tip: Electrical personnel, due to the type of apparatus or equipment involved, may need to use other Codes and Standards in addition to UL 508A.UL 508(A) covers five main categories with requirements designed to judge and evaluate industrial control devices and accessories, and they are as follows:

(1) Construction

(2) Performance

(3) Rating

(4) Marking

(5) Instruction and use

Design Tip: The rules and regulations in UL 508A cover devices rated at 1500 volts or less. Such rules and regulations must be reviewed very carefully before attempting to apply them to the design of such apparatus.

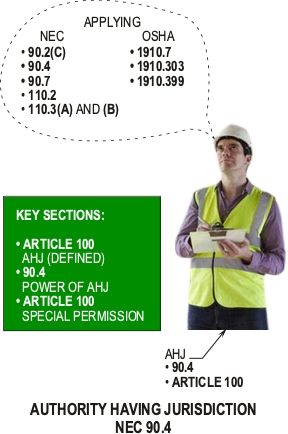

Authority Having Jurisdiction

The authority having jurisdiction (AHJ) is the organization, office, or individual responsible for “approving” equipment, installations, or procedures.

Design Tip: The phrase “AHJ” is used in NFPA documents in a broad manner since jurisdictions and “approval” agencies vary, as do their responsibilities. Where public safety is primary, the AHJ may be a federal, state, local, or other regional department or individual such as a fire chief, fire marshal, chief of a fire prevention bureau, labor department, health department, building official, electrical inspector, or others having such authority. For insurance purposes, an insurance inspection department, rating bureau, or other insurance company representative may be the “AHJ.” In many circumstances, the property owner or his or her designated agent assumes the role of the “AHJ” at government installations or county areas not requiring a permit and inspection. (See definition of AHJ in Article 100)

The AHJ has the option of permitting alternative methods where specific rules are not established in the NEC. This allows the local authority to waive specific requirements in industrial occupancies, research and testing laboratories (NRTL), and other occupancies where the specific type of installation is not contemplated in the NEC requirements.

The AHJ may waive a new NEC requirement during the interim period between the acceptance of a new edition of the NEC and the availability of a new product, construction, or material redesigned to comply with the increased safety required by the new NEC edition. It is difficult to establish a viable future effective date in the NEC because the time needed to change existing products and standards and to develop new materials and test methods is not usually known at the time of adoption of the new requirement in the NEC.

It is also the responsibility of the local authority (AHJ) enforcing the NEC to interpret the specific rules and regulations of the NEC.

By special permission, the AHJ has the responsibility of giving the engineer, contractor, electrician, etc. written consent of his or her decision to waive a requirement in the NEC pertaining to a specific installation. For example, see 90.2(C) and 230.2(B).

Retrofit kit is a general term for a complete subassembly of parts and devices for field conversion of utilization equipment.

Note: A new definition has been added to address the meaning of retrofit kit. (See Illustration 6 below)

Design Tip: The UL White Book is known in the electrical industry as the “Guide To Information for Electrical Equipment”. This book covers retrofit devices or kits consisting of parts and/or sub-assemblies intended for field installation in various types of equipment by qualified service personnel. UL Listed equipment that requires modifying, revising, or replacing the circuitry internal to the listed equipment. These products have been investigated to determine that, when installed in accordance with the manufacturer’s installation instructions, they do not adversely affect the operation of the specified equipment involved. The parts that form the enclosure of the listed product may be modified in the field, to fulfill the installation of the kit, but not replaced. Installation instructions are provided with each kit and include information identifying the specific equipment into which the kit may be installed.

Illustration 6